PLANET PRESERVATION

Planet Preservation

We commit to the efficient use, reuse, and restoring of agriculture and fisheries resources, as well as better management of our environmental impacts by decreasing our water and energy consumption, lessening our greenhouse gas emissions, and actively monitoring our waste generation as we continue to grow our business and serve Filipinos.

Tuna Sustainability

Leading the advocacy for more sustainable fishing practices and responsible sourcing as well as improving how we manage our impacts as part of the solution

Using Skipjack Tuna

Stocks of skipjack are deemed to be at healthy levels by the International Seafood Sustainability Foundation (ISSF) in 2023.

Traceability

All tuna raw materials are traceable at the source – vessels are registered at the Proactive Vessel Register and audited by a third-party assurance group, MRAG Americas. This ensures that we only source from suppliers who comply with industry best-practices and conservation measures.

International Seafood Sustainability Foundation (ISSF)

CNPF is a member of the International Seafood Sustainability Foundation (ISSF). CNPF also sits on the Board of the ISSF to help shape sustainable tuna fishing practices globally.

Aligning with Other Global Standards and Industry Associations

We are also a member of the Global Tuna Alliance—a market-led initiative that issued the Tuna Traceability Declaration in 2020 in support of the U.N. Sustainable Development Goal 14: Life Below Water.

In 2021, General Tuna adopted the GDST Standards and Guidelines for Interoperable Seafood Traceability Systems, Version 1.0 as part of the global initiative to make global seafood traceability more reliable and more affordable by allowing for interoperability across seafood traceability platforms. This is an important development for the industry to combat illegal fishing and unethical labor practices.

42% of our fisheries are certified by Marine Stewardship Council (MSC). To further our MSC Certification, we are working with the Bureau of Fisheries and Aquatic Resources (BFAR) to manage a Fishery in Progress (FIP) in the Western Central Pacific Ocean High Seas Pocket 1 for 36 Philippines-registered vessels. This FIP addresses a common set of harvest rules and enforcement tools and capabilities to ensure sustainable stocks of Yellowfin and Skipjack tuna. Importantly, the FIP contributes to nation-building as it encompasses all Philippines-registered vessels, thereby helping to make our local fishing industry more competitive on international markets.

To read more about Tuna Conservation, visit the Purchases Assessment page on our website.

Natural Resource Efficiency

Water Consumption Reduction

Continuously improving by invest in technology and deepening our understanding of our water-related impacts on the local communities where we source our water

CNPF ensures the highest water quality standards across all our business units by utilizing a mix of sustainably sourced (deep well water and purified district) water. Our rigorous monitoring, sampling, and testing protocols across production processes strictly adhere to quality standards, reflecting our commitment to operational excellence and environmental stewardship.

In our Tuna, Coconut, and Sardines plants, we reclaim condensate, turning what would be waste into a resource. For instance, the water from softener backwash finds new life in washing processes, and we employ water recycling in our vacuum filling machines. In our Meat business, we’re making significant strides in water conservation by reusing cooling water from previous cycles. We use reverse osmosis systems across our business units to reuse water wherever feasible.

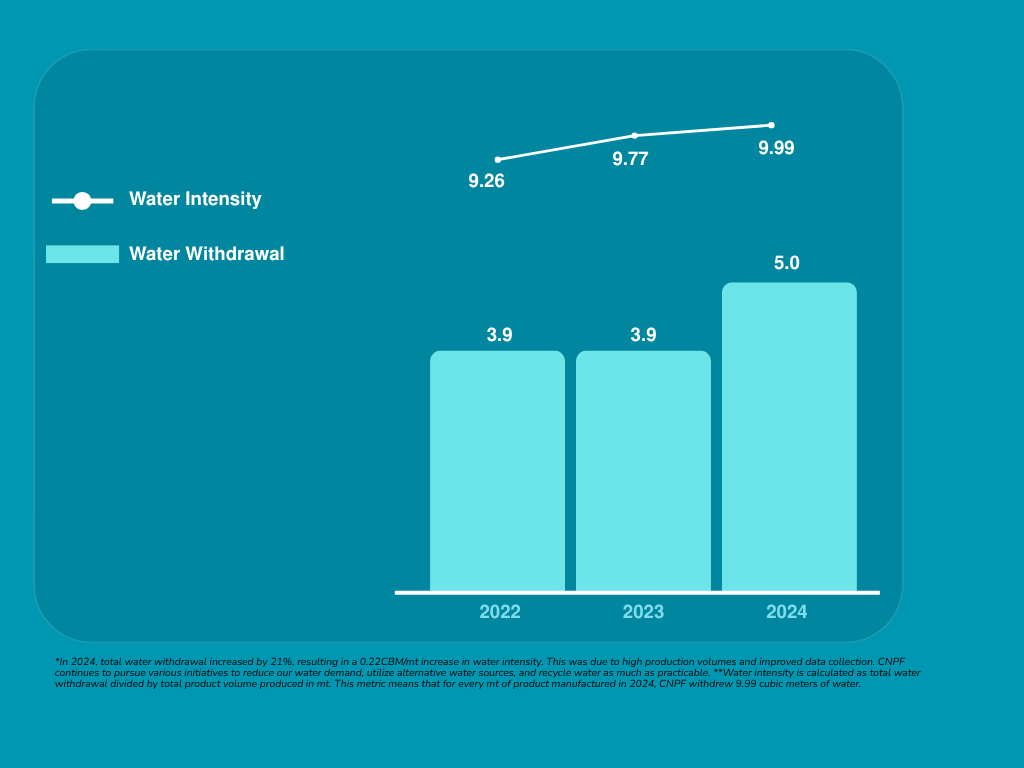

In 2024, total water withdrawal increased by 21%, resulting in a 0.22CBM/mt increase in water intensity. This was due to high production volumes and improved data collection. CNPF continues to pursue various initiatives to reduce our water demand, utilize alternative water sources, and recycle water as much as practicable.

Water intensity is calculated as total water withdrawal divided by total product volume produced in mt. This metric means that for every mt of product manufactured in 2024, CNPF withdrew 9.99 cubic meters of water.

Energy Consumption Reduction

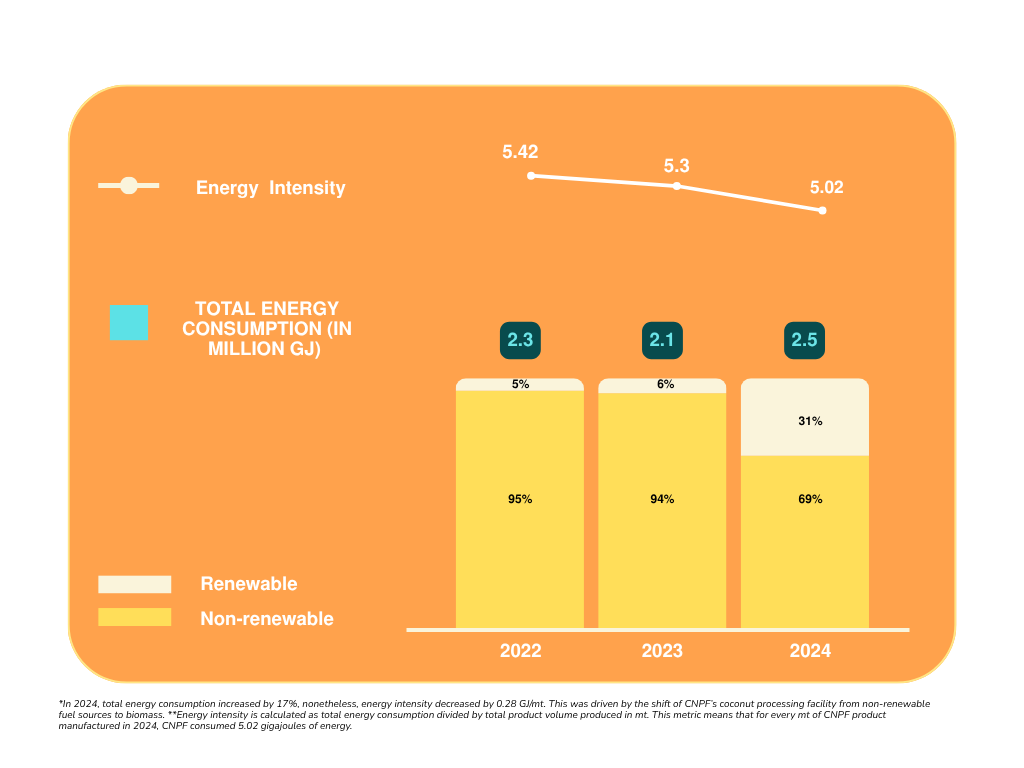

Implementing energy conservation across all plants resulting in an improvement in our energy intensity of 3% versus the year before.

Our Tuna plant has 100% energy-efficient LED lighting, and we have additionally replaced other systems, equipment, and machinery with more energy-efficient technology. Our Sardines plant has upgraded their motors to high-efficiency models that support both their cannery and fishmeal operations. We are also diversifying our energy mix to increase the share of renewable energy such as solar power.

In 2024, total energy consumption increased by 17%, nonetheless, energy intensity decreased by 0.28 GJ/mt. This was driven by the shift of CNPF’s coconut processing facility from non-renewable fuel sources to biomass.

Energy intensity is calculated as total energy consumption divided by total product volume produced in mt. This metric means that for every mt of CNPF product manufactured in 2024, CNPF consumed 5.02 gigajoules of energy.

Environmental Impact Management

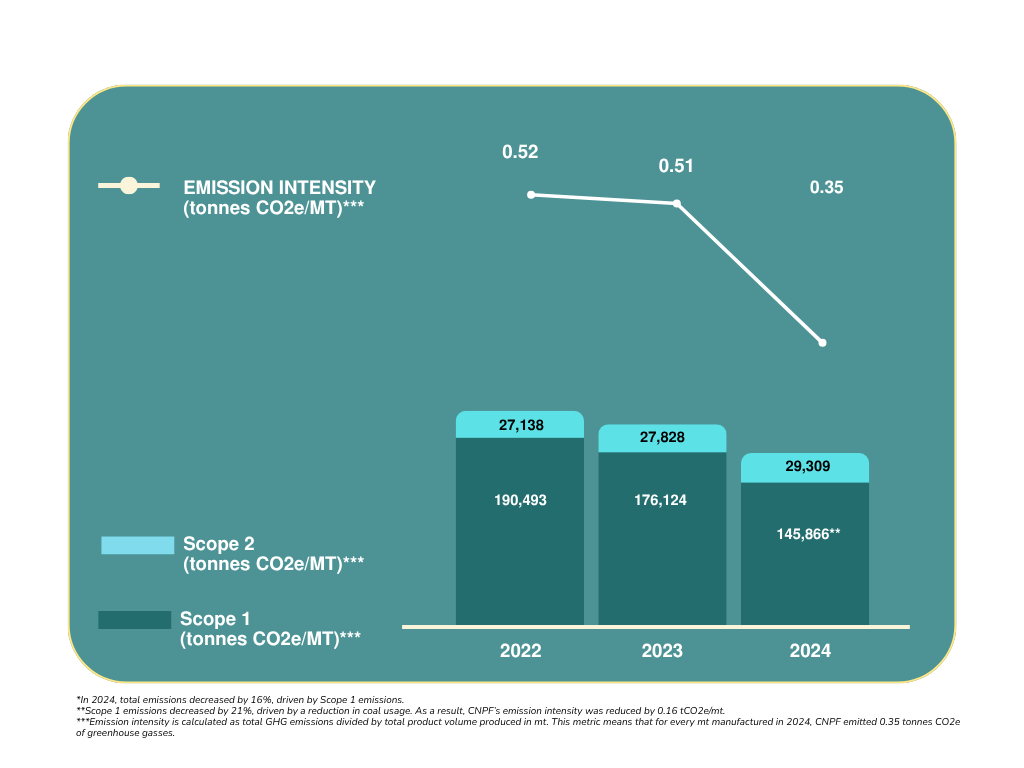

Greenhouse Gas Emission Reduction

Increasing the share of renewable energy in our energy mix and implementing new waste-to-energy initiatives.

During the year, the Company expanded its solar power facility in General Santos City, where it houses its largest manufacturing hub in the country for tuna and coconut. From a capacity of 5.2Mw, the operational solar capacity now stands at 8.6MW, representing a 65% increase.

CNPF’s tuna and coconut facilities predominantly use clean energy sourced from a hydroelectric power plant through the grid. In 2021, the Company commissioned its first solar PV plant in a move to double down on its commitment to more sustainable manufacturing practices.

Spotlight Story

Coconut Processing Facility Biomass Boiler Improvement

In 2024, CNPF’s Coconut processing facility made considerable progress in its capability to utilize biomass as fuel. After the initial investment in biomass capability in 2023, the business segment converted the rest of its boilers to be able to process waste coconut shells as fuel. By increasing biomass capability in the manufacturing process, our coconut processing facility takes one more step towards more eco-friendly operations while still ensuring its bottom line is met in terms of production—a win for the environment, our people, and the business.

These boiler improvements not only reduced health hazards for operators and boiler crew, but it also drastically improved cleanliness in the area. Previous processes would necessitate regular de-ashing and ash hauling due to the byproducts of using coal as a fuel source. With these improvements, coal ash waste was reduced close to zero percent from previously near 40%.

These improvements also mean that the boilers now have zero air pollutants and reduced carbon emissions.

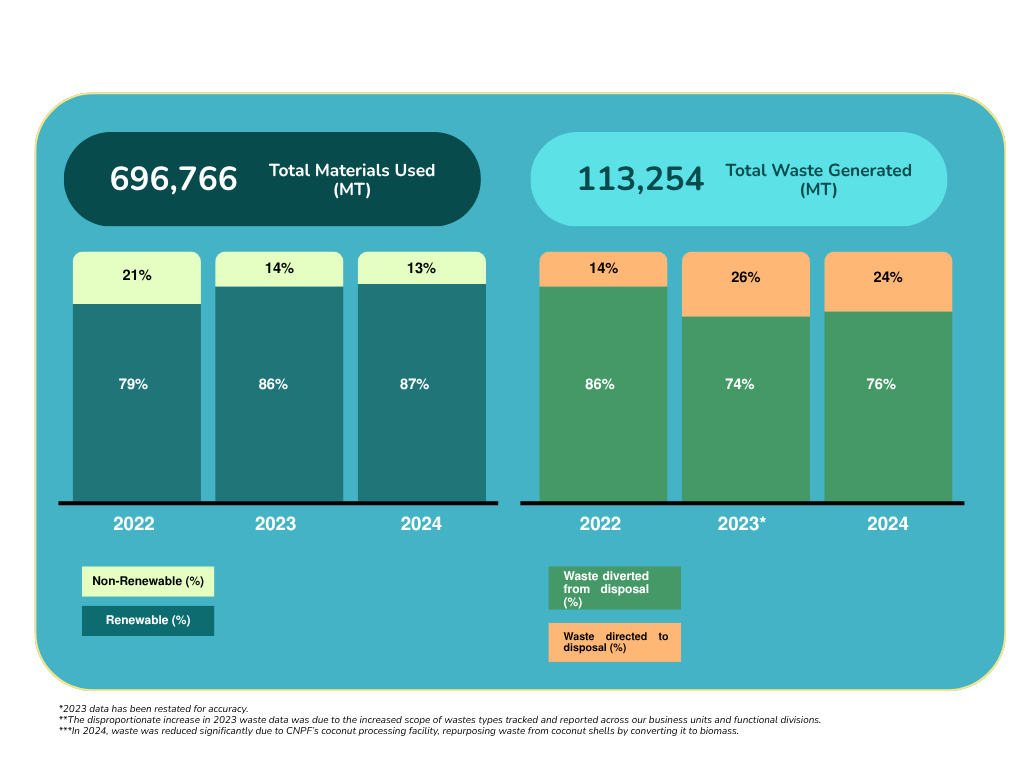

Landfill Waste Reduction

In our Coconut business, we strive to incorporate as much of the fruit as possible in a wide range of products such as Coco Mama (cream and meat) and OEM products like coconut water, coconut oil, desiccated coconut, and coconut flour, among others. To minimize waste, we are exploring sustainable uses for coconut shells and husks, for example as a biofuel. In our Tuna business, excess fish parts are turned into byproducts such as fish meal, fish oil, and fish soluble.

In compliance with the Ecological Solid Waste Management Act, all business units conduct onsite segregation of their operational waste as part of daily operations. We sell recyclables from our operations such as scrap metals, plastics, paper, and cardboard to scrap recyclers, while accredited haulers collect our general rubbish for disposal at landfill. All our business units have systems in place to monitor and measure the amount and type of waste from their operations and report quarterly to our Sustainability Steering Planet Subcommittee.

We prioritize materials that are recyclable, renewable, or biodegradable. Our current packaging range—from tin cans and metal lids to glass bottles, plastic containers, paper labels, and cardboard cartons—is designed to support recyclability. Additionally, we actively collaborate with partners to maximize the recycling and co-processing of plastic packaging, in an effort to reduce our environmental footprint. For further information see this report’s section on Net Zero Plastic Waste.

We are committed to managing the waste we generate, to recover and process these into resources that can be reused whether for our operations or for external processes.

*CNPF improved waste data collection, increasing the scope of business units and waste types tracked, resulting in an increase in the total waste generated reported for the year. The was primarily driven by reporting more general landfilled waste, packaging waste, and food waste from our operations that are processed into fishmeal and other by-products.

Plastic Waste Footprint Reduction

We continuously seek out viable eco-friendly substitutes to single-use plastics and explore ways to diminish our plastic dependency. Our Tuna business has replaced plastic stretch films with reusable wraps for palletized empty cans and finished goods in logistics and transport, reducing plastic waste by over 56% since implementation of these initiatives in 2022.

70-80%

of our brands use paper and tin packaging which are more easily recycled

2024 marks our fifth year of committing to reducing our brands’ plastic footprint by 100% through an offsetting mechanism, ahead of the 40% footprint reduction required by the Extended Producer Responsibility Act of 2022.

We’ve advanced our commitment with now 14 brands under the Plastic Cleanup Program of PCX, encompassing all CNPF brands using flexible plastic packaging. We are committed to incorporating all new CNPF brands that use flexible packaging into our plastic waste reduction program. To offset our footprint in 2024, we purchased 2,904 mt worth of plastic credits.

Net Zero Plastic Waste Brand Certifications

We are pleased to share that all our brands that make use of flexible plastic packaging have been certified as Net Zero Plastic Waste Brands by Isla Lipana & Co. (PriceWaterhouseCoopers).

The certified brands were the only CNPF brands that use post-consumer flexible plastic packaging during the audited period, making up 20-30% of our branded business.

See certifications here – Net Zero Plastic Waste Certifications

Learn more about our plastic waste footprint reduction program here.

Spotlight Story

Saving Our Seas

CNPF reinforced its commitment to the environment this year with the expansion of its “Saving Our Seas” campaign, in partnership with the impact organization HOPE and through its Aling Tindera Waste-to-Cash program. While this is but a small step towards addressing the plastic waste problem in the Philippines, we are steadfast in our belief that promoting the circular economy and mobilizing communities are fundamental to make progress.

The campaign, launched in 2023 in conjunction with Earth Hour, kicked off with volunteer effort supported by 212 individuals who collected plastic waste in Mabini, Batangas, a hotspot for biodiversity. To ensure the sustainability of these efforts, CNPF has installed multiple plastic waste collection points along the coast. These serve not only as disposal sites but also as economic opportunities for the community. The sari-sari store owners, who are part of HOPE’s Aling Tindera Waste-to-Cash program, play a pivotal role in managing these points. They collect, accumulate, and ensure proper recycling or upcycling of the waste.

At the close of 2023, the Aling Tindera, in coordination with Saving Our Seas, had successfully collected over 9,000 kilograms of plastic waste in total.

The overarching aim of CNPF is to empower Filipino communities to fight against plastic pollution, emphasizing that the responsibility for preventing pollution begins at home, regardless of one’s proximity to the coastline.

Our Activities as a Plastic Cleanup Partner of PCX

CNPF’s waste-to-cash program, developed in collaboration with PCX, empowers women-owned sari-sari stores in Manila to serve as collection hubs for post-consumer plastic, providing residents with a new income source while promoting sustainability.

We have two collection points stationed in Barangays 432 and Baseco Port, and 14 located in Anilao, Batangas. They are managed by women micro-entrepreneurs, incentivizing community-wide collection efforts. This initiative enhances the livelihoods of residents and store owners, increasing the average annual income of Aling Tindera participants (AT’s) by an average of 48% nationwide, and plays a crucial role in our efforts to better manage post-consumer plastic waste.

Another key inclusion in our Plastic Waste Reduction initiatives is “Century Tuna Saving Our Seas” collaboration with HOPE, the Philippines’ first certified B Corp,. This initiative goes beyond collecting plastic for reuse and recycling and emphasizes community involvement into plastic waste reduction and management efforts.

Some highlights of our 2024 activities include:

- April 2024: PALIT PLASTIC PROJECT in La Union with 16 out 20 LGUS participating

- September 2024: INTERNATIONAL CLEAN-UP DAY in Brgy. Mainit, Mabini, Batangas

- September-October 2024: SCHOOL PLASTIC DRIVE (Talaga Elementary School, Mainaga-San Francisco School, Mabini Central School) in Mabini, Batangas

Overall, the Saving Our Seas collaboration marked a record high of almost 60,000 kgs of plastic waste diverted in 2024, four times the 15,000 kgs recorded in 2023.

Supply Chain Management

Supplier Credibility

Seeking business partners that meet our commercial standards, comply with relevant government regulations, and align with our social and environmental aspirations as a responsible member of the community.

Instituted the Supplier Code of Conduct and Ethics (SCOCE) that outlines the company’s stance with respect to responsible sourcing and supply chain sustainability

100% of current active suppliers signed and acknowledged the SCOCE as a requirement to work with CNPF

Local Sourcing

To support the local economy, we allocate over 56% of our total procurement budget on suppliers registered in the Philippines. In 2024, 100% of the raw materials for our Coconut business were sourced from local farms. Through our Agripreneur programs, we source approximately 80% of the fresh produce we use in Tuna from local farmers. Our Sardine business also works with local fisherfolk, sourcing most of its major raw materials requirements locally.

Responsible Sourcing

At Century Pacific Food, Inc., we believe in the importance of responsible sourcing as part of building a more sustainable food system. As we continue evolving our sourcing and product development, we aim to strike the right balance—ensuring food safety, quality, and affordability, while strengthening the resilience and responsibility of our supply chains.

We have a robust vendor accreditation process to ensure the quality and safety of our products and the credibility of our partners, who are subject to periodic audits. Furthermore, we have institutionalized the Supplier Code of Conduct (SCOC). To learn more about SCOC, click here.

As one of the leading manufacturers of tuna products both locally and worldwide, we recognize that the longevity of our tuna business hinges on the sustainability of the seafood industry. We aspire to be a leader in tuna sustainability. We diligently comply with international regulations on conservation measures. To learn more about our sustainable tuna fishing practices, click here (tuna purchase assessment).

We have also kickstarted our Sardine Sustainability initiative, Sustenido Bulan, aimed at promoting sustainable fishing practice among local fisherfolk. To learn more about Sustendito Bulan, click here.

At present, Century Pacific Food, Inc. does not use fresh eggs in any of our products. Nevertheless, for any future product innovations that may use such ingredients, our goal is to source only cage-free fresh eggs. Furthermore, we are actively transitioning all egg ingredients to cage-free sources and are aiming to complete this shift by 2030 as part of our commitment to responsible sourcing and animal welfare. We will provide annual updates on our progress toward this goal.